wire edm machine how it works

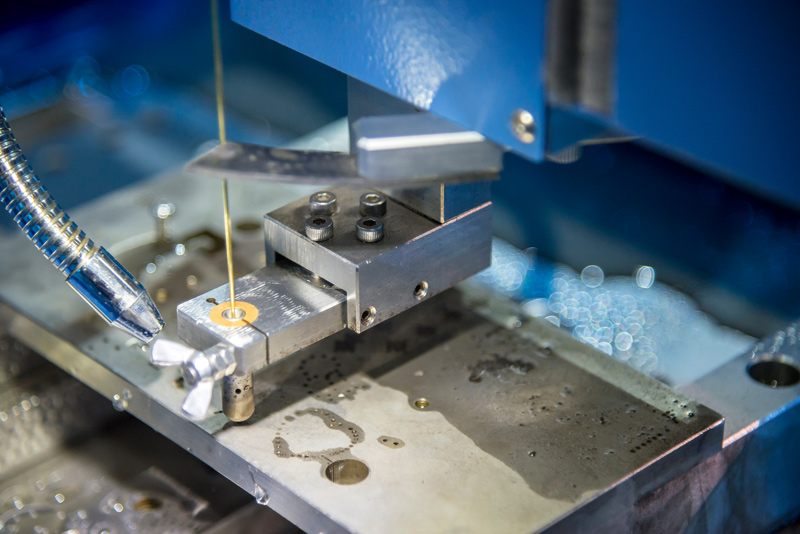

An EDM Wire-cut machine uses a continuous thin electrically conductive wire as the electrode to cut profiles on the workpiece and this process is called wire cutting. An arbor the electrode holder and the dielectric fluid.

Wire Edm Machining Cutting Services Moon Tool

Wire EDM machining works by creating an electrical discharge between the wire or the electrode and the work piece.

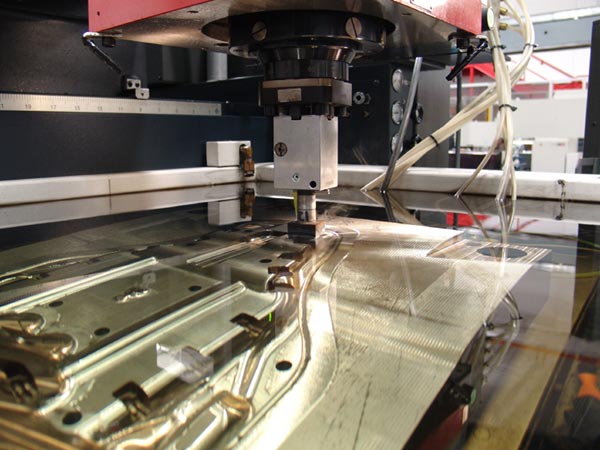

. EDM is a machining process that uses electrical currents to cut metal. Wire electrical discharge machining also known as wire EDM is a contact-free machining method that uses a thin metal wire to conduct an electrical current. A wire EDM machine looks like a bandsaw that has a wire for a blade.

An edm machine contains three main components. In wire EDM machining the material is removed from the workpiece by a series of rapidly recurring current discharges between the wire or the electrode and the workpiece. Short interesting video on the fundamentals of the electrical discharge machining.

As the spark jumps across the gap material is then removed from the. The wire of this type of EDM unit emits sparks on all sides requiring that the. Wire EDM Electrical Discharge Machining is a second form of electrical discharge machining that is sometimes referred to as wire erosion wire burning or spark EDM.

No actual contact is made between the. Your Wire EDM machine uses a thin. The arbor is the.

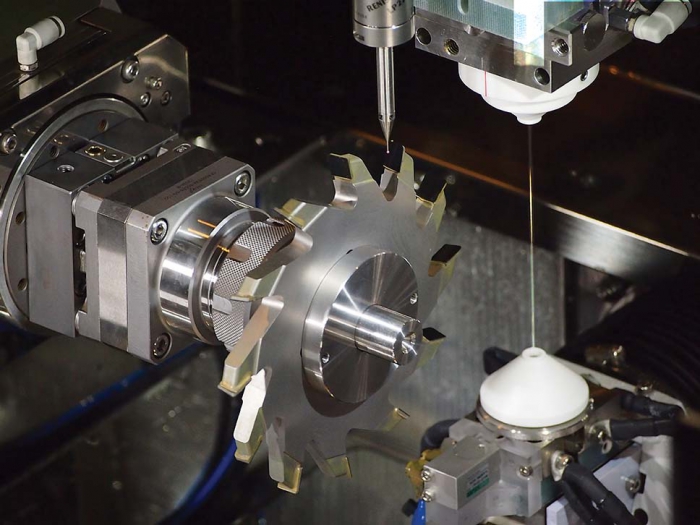

Wire Electrical Discharge Machining Wire EDM is a plasma machining process that uses an electrical discharge between a wire and a conductive workpiece. While this was just our first round of prototyping we will continue to work on this DIY Wire EDM machine and turn it into a proper homemade CNC EDM Machine. Basic introduction to the wire EDM and high-speed small hole EDM processes.

The type of electrical discharge machining EDM Machine Inc. Material is removed from the work-piece surface by continuous spark discharges between the electrode and work-piece surface. At a certain thickness wire EDM will simply cause the metal to evaporate thereby eliminating potential debris.

Wire EDM also known as Wire-Cut EDM works in a very similar way using a rapidly charged conductive metal wire to melt the material. Wire EDM Electrical Discharge Machining is a second form of electrical discharge machining that is sometimes referred to as wire erosion wire burning or spark EDM. How It Works.

How Wire EDM Works. Make sure to follow our CNC. A thin wire is utilized.

A thin wire is utilized. To begin the cut the wire must cut into the metal from the side or through a hole that is drilled. A wire EDM unit can be programmed to cut complex shapes small or large to a dimensional tolerance of 00001 inch and can be trusted to do so repeatedly and reliably.

Wire EDM machining works by creating an electrical discharge between the wire or the electrode and the work piece.

What Is Wire Edm Electrical Discharge Machining Xact

Wire Edm Machining Wire Cutting Services In China

Wire Edm Guide To Edm Wirecut Machine Process Uses Fine Metalworking

How Does Wire Edm Work Laszeray Technology Llc

Edm Focus Turns To Throughput Ease Of Use Automation Cutting Tool Engineering

Cnc Wire Cut Cnc Wire Edm Wire Edm Wire Edm Machine Working Principle Youtube

Edm 101 Electrical Discharge Machining Basics

What Is Wire Edm Process Benefits Applications

Wire Electrical Discharge Machining An Overview Sciencedirect Topics

Wire Edm Machining For Extreme Accuracy Explained Mellowpine

Punch Tools Edm Wire Edm Edm Wire Cutting Edm Extrusion Wire Erosion Edm Wire Burning Wire Edm Vancouver Electrical Discharge Machining

What Is Wire Edm Electrical Discharge Machining Xact

How Wire Edm Works Missouri S Wire Edm Machine Shop

News Brass Wire For Wire Cut Machine Die Sinking Electrical Discharge Machine Fully Automatic Wire Cutting Machines Novick Digital Equipment Co Ltd